Reprap - electronics

Generation 7 Electronics

I am using Markus Hitter's Generation 7 electronics.

One of the remarkable features of the Generation 7 electronics is that it consists entirely of through-hole components. There are no surface-mount components at all (with the exception of the break-out boards). I think it's fair to say that through-hole components are quite rare in most applications nowadays, and they are impracticable in many cases due to their larger PCB footprint.

Another important feature is that the Gen7 electronics is a single-board solution for Reprap electronics.

The board features an Arduino-compatible AVR 8-bit microcontroller. The firmware is an Arduino bootloader.

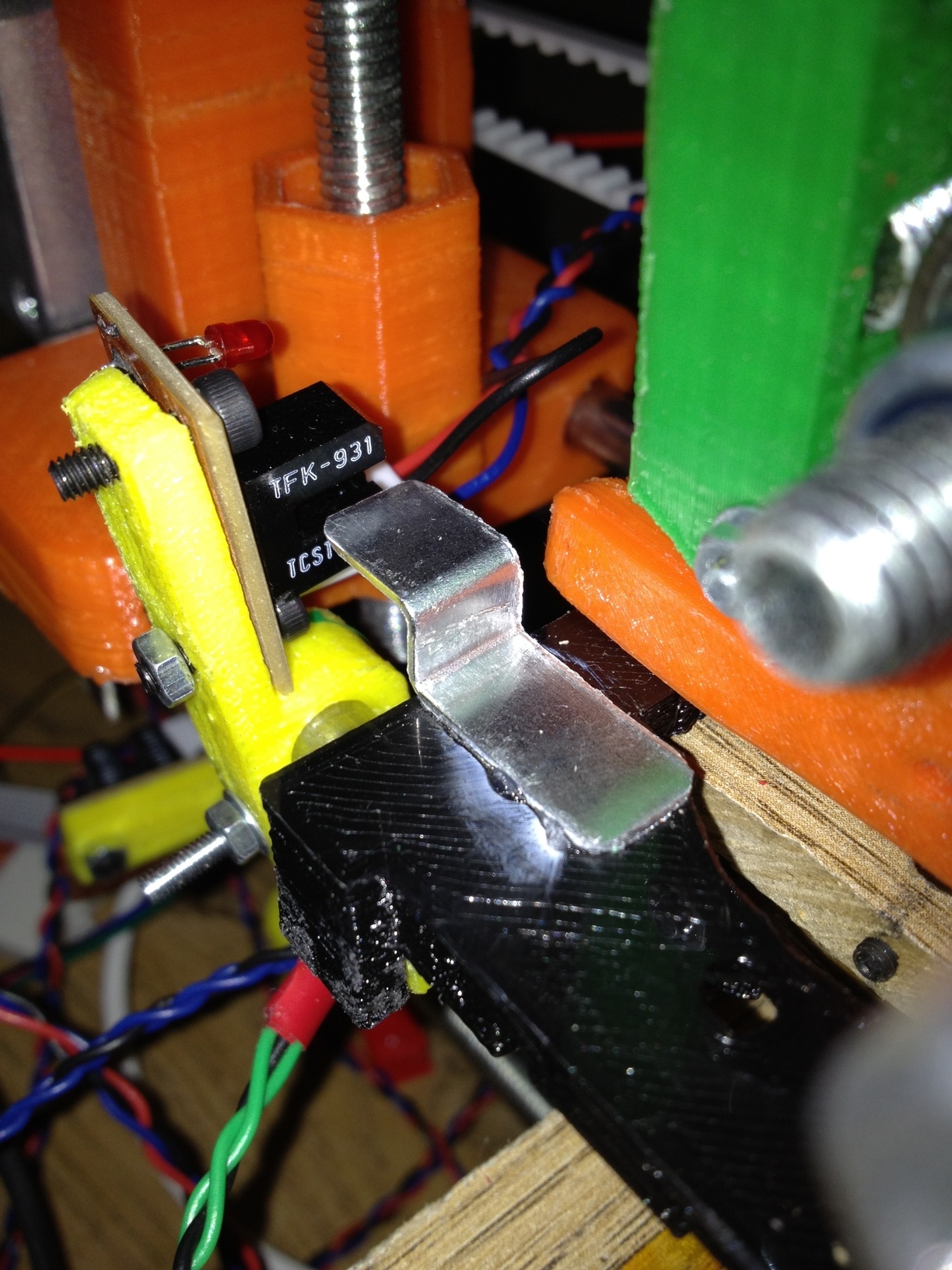

Optical end-stops

In order for cartesian positioning to work correctly, the controller board needs to receive a signal whenever the extruder reaches position zero on an axis. This is accomplished using mini-circuits known as "end-stops". Whenever the minimum coordinate on an axis is reached, the corresponding endstop is triggered, and sends a message to the controller board - so the motion along that axis comes to a halt.

Two types of end-stops can be used on a Reprap - mechanical or optical. I am using the optical types. These are small circuits consisting of a combined photoemitter-photodetector. A strip of opaque material is attached to the extruder in such a way that - whenever the minimum coordinate on an axis is reached - this strip blocks the passage of light between the emitter and detector. Three end-stops are needed on a Reprap - one for each axis.

The strips can be made from any opaque material. I chose 1mm aluminium sheet, as it's easy to work with.

- Log in to post comments